|

Producing biodiesel from coffee oil |

|

|

Drying Coffee:

Here you can see about one and half buckets of coffee grounds being sun dried. It took about one day. If spread thinner, a couple of hours would have been enough. |

|

|

Test Sample Used:

50 grams of coffee grounds were put into a glass extraction thimble. The goal is to find what percentage (by weight) of the coffee grounds is coffee oil. |

|

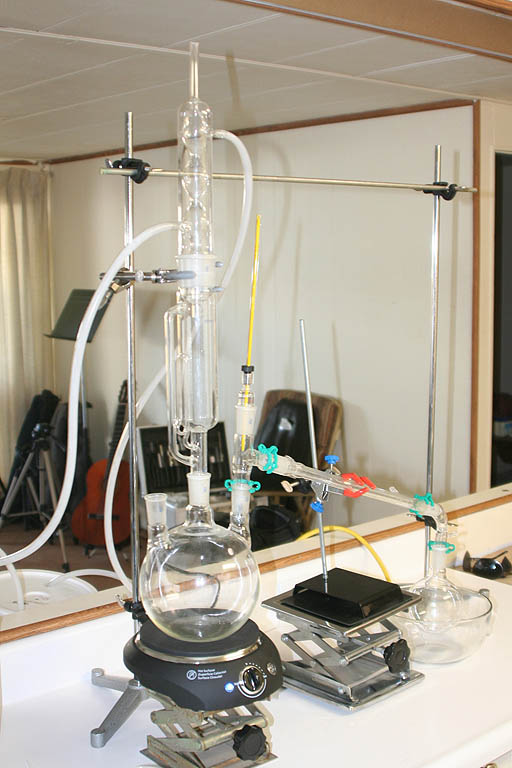

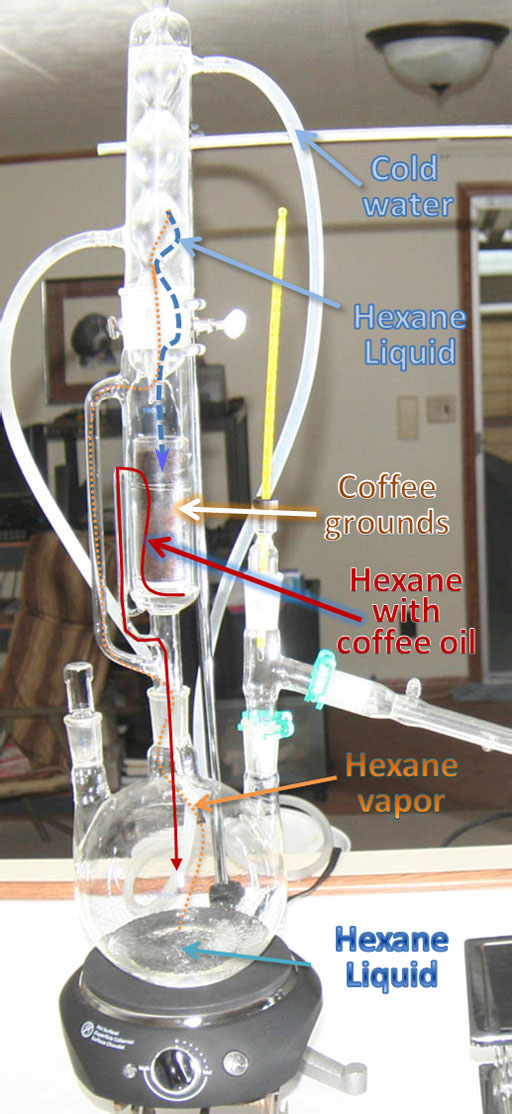

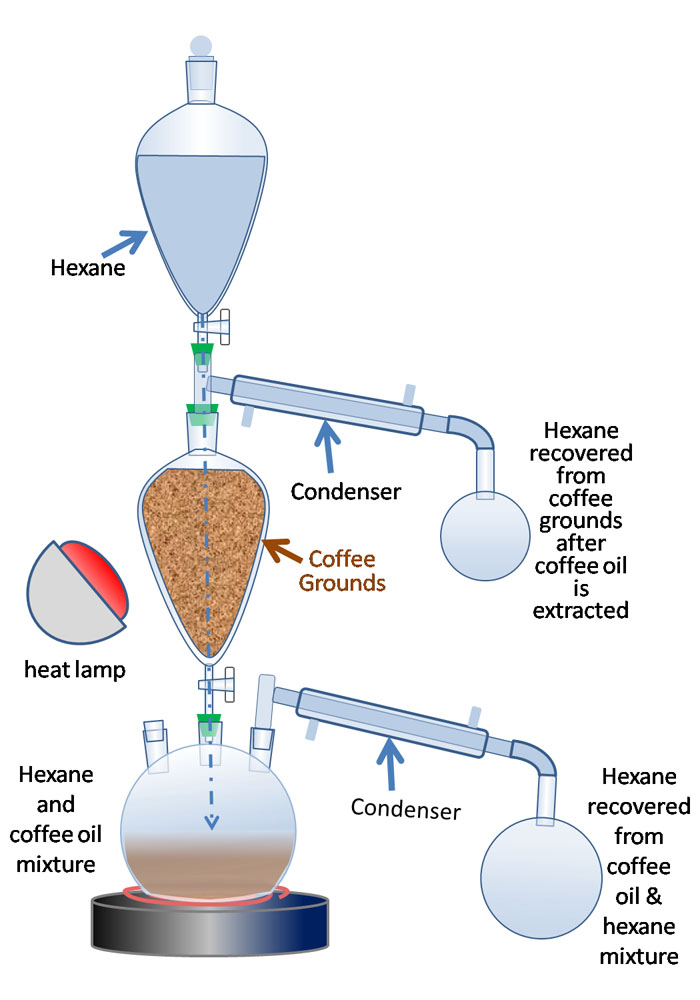

Soxhlet Extraction Apparatus with Recovery Distillation Accessory: The tall part of the left is for the extraction of the coffee oil from the coffee grounds. The tube and flask on the right is for recovery of the hexane solvent that will be used to extract (dissolve) the coffee oil from the coffee grounds. |

|

|

Soxhlet Extraction Apparatus:

This is the apparatus that extracts the coffee oil from the coffee grounds. Liquid hexane (a 6 carbon chain similar to gasoline) is boiled in the bottom flask. Hexane vapor travels up and through the side arm. It condenses back to liquid in the cool condenser at the top. Liquid hexane drips down on a container full of coffee grounds. The hexane dissolves the coffee oil. Once the contaner is full of hexane, a small glass tube on the left automatically siphons out the hexane with the dissolved coffee oil. That goes back into the bottom flask. The process repeats as more hexane vapor condenses and washes the coffee grounds. This setup allows the hexane to extract the coffee oil several times. It's efficient and uses the least amount of hexane to do the job. |

|

|

Coffee Grounds Weighed:

This is the extraction thimble. 50 grams of coffee grounds were placed in the thimble. The thimble was lowered into the top of the soxhlet extraction glassware.

|

|

|

Boil the hexane: The hot plate is turned up and the hexane starts to boil. It has a boiling point of 69°C (156°F). |

|

|

Hexane liquid drips on coffee grounds:

The vapor travels up the side glass tube and condenses on the cold condenser. It drips down on the coffee grounds and fills the thimble with hexane. Below the thimble you can see the coffee colored liquid. That is a mixture of hexane and coffee oil. Once the hexane/coffee oil mixture fills up to the top of a small glass side tube, the mixture will siphon down into the large bottom flask. |

|

Coffee oil in flask:

As the hexane/coffee oil mixture siphons into the bottom flask, you see that it goes from clear to a light coffee color. Each time the thimble fills with hexane and siphons out, the liquid in the flask gets a little darker. |

|

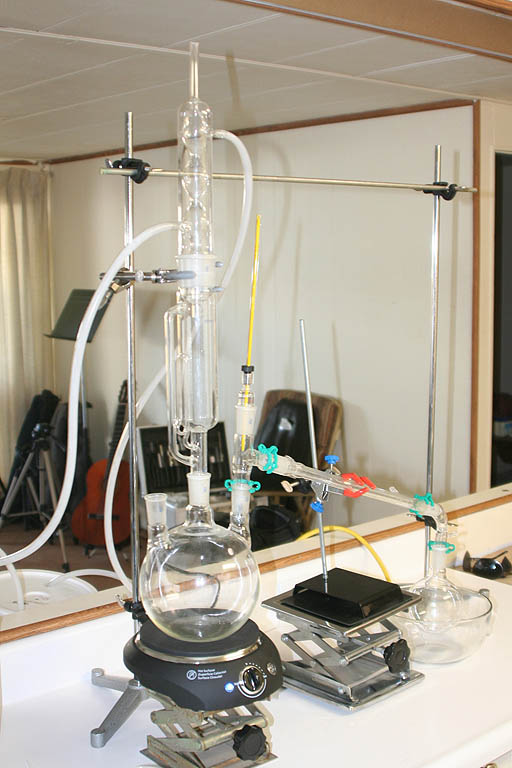

Coffee oil in flask: Here is another picture of the setup. Notice the coffee colored liquid below the thimble. That indicates that coffee oil is being extracted. |

|

Extract become clear: Each time the thimble fills with hexane, the hexane/coffee oil mixture gets lighter because less and less coffee oil is left. I let it fill 5 times. It took about 10 minutes for the hexane to fill the thimble each time. Here the hexane/coffee oil mixture is quite light meaning most of the coffee oil has been extracted. |

|

Separate hexane from coffee oil and recover the hexane: Now that all of the coffee oil is extracted and in the hexane in the bottom flask, the task is to distill off the hexane leaving just the coffee oil. The side arm is used for that. The tube held by the orange clamps is another condenser. Cold water runs through it. It will condense the hexane vapor allowing the liquid to run down hill to another flask on the right. |

|

A partial vacuum speeds up the collection of hexane: In this picture, you can see I added a flask and pump that creates a partial vacuum. This allows the hexane to boil at a lower temperature and quicker. Ice surrounds the round collection flask to prevent the hexane liquid from evaporating too easily. About 80% of the hexane was recovered. To be economical, the hexane recovery has to be much better. Actually, I realized later that a lot of hexane was held by the coffee grounds that I let air-dry. If that hexane was reclaimed, I think there would have been 95% hexane recovery. |

|

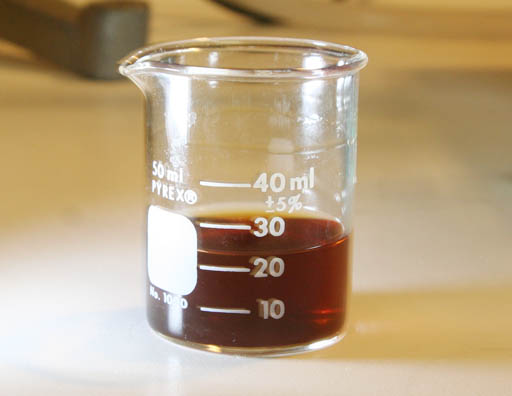

Coffee Oil: After the hexane is boiled away, all that is left is coffee oil. There's not much oil because there were only 50 grams of coffee grounds used. |

|

Pure Coffee Oil: I collected about 22 mL of coffee oil; however, there was still some hexane left. The next day the beaker had 12 mL of coffee oil. I figure after all hexane has evaporated, there will be about 6 mL of pure coffee oil left. |

|

Before and After: The coffee grounds on the left were what the grounds looked like before the extraction. The coffee grounds on the right are after the coffee oil had been extracted. Note that those are quite a bit lighter. The ground weighed 45.4 grams after the coffee oil was extracted. It weighed 50 grams before. So that's 4.6 grams of coffee oil that was extracted. So the coffee oil is 4.6/50 (9.2%) of the weight of the coffee grounds. |

| Below is the next setup I will test. It will allow about 3 pounds of coffee ground to be extracted at a time. It will require more hexane solvent than the soxhlet extractor used above, but if nearly all hexane is recovered, that's not an big issue. The below apparatus is also designed to recover the hexane that is left in the coffee grounds after that last soaking with hexane. I found out that about 75% of the hexane needed to cover the grounds does not drain out but stays bound to the coffee grounds. So a second distillation of hexane will be done after the coffee oil is extracted. |

|

| For questions or comments, contact me, Ken Costello, at costello@chemistryland.com |